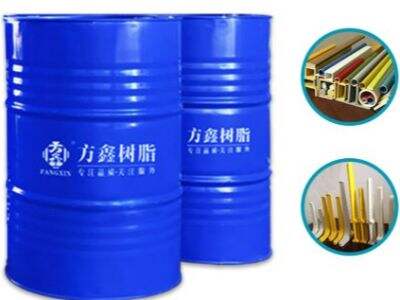

Tražite li najbolje pultruzione rezuve za vaše FRP proizvode? Tražite dalje. Želeli smo da sakupimo samo najbolje pultruzione rezuve koje će vam pružiti sve što tražite od materijala.

Prednosti:

U suštini, za proizvodnju FRP proizvoda, Fangxinove pultruzione rezuve su korisne kada je riječ o stakloslovu. One imaju mogućnost primjene u mnogim područjima; mogu poslužiti kao zamjena drvetu, metalu i betonu na primjer. Takođe su prijenosne, jake i posjeduju visoke mehaničke osobine.

Inovacija:

Odlučivanje kada je riječ o pultruzionim rezinama je mudro, stoga je potrebno uzeti u obzir inovacije. Trenutno, neki od najviših Pultruzijska rezina на тржишту су relativno novi na tržištu sa nekim od karakteristika fleksibilnosti, snage i gustoće. : ili okolišnih uticaja; oni takođe otporni su na različite uslove sredine.

Sigurnost:

Pultruzioni leja su opasne kemijske tvari koje treba rukovati sa paznju, pa je sigurnost prvenstvena pri obradi ovih leja. Najbolja pultruziona leja uvijek se razvijaju i pripremaju uz obzir na sigurnost, bez zabranjenih toksičnih elemenata ili VOC-a. Pored toga, obično se dobavljaju sa jasnim uputama za korišćenje kako bi se smanjio rizik od nesreće.

Upotreba:

Nova pultruziona leja mogu se primeniti posebno u različitim područjima. Ova leja su posebno priljubljena u automobilskoj industriji, građevinarstvu brodova, građevinarstvu i u letalnoj industriji. Takođe su određene kao pogodne za pojačanje cevi, okvira prozora, električnih i elektronskih proizvoda i drugo.

Kako koristiti:

Da biste koristili Pultruzijske rezuine, posebna pažnja mora biti posvećena preporukama proizvođača rezuina koje se koriste. Presipite tačne proporcije rezuina i tvrditelja zajedno u posudu. Morate da se uvjerite da nosite odgovarajuću zaštitnu opremu kao što su rukavice, ochrane za oči i respirator prilikom rukovanja ovim rezuinama. Rasprostranite mešavinu rezuina jednoliko na površinu koja se tretira. Na kraju, dopustite Rešina za FRP listove da se uspostavi prema uputstvu, obično putem zatvaranja.

Usługa:

Stoga, kvalitetni posleprodajni servisi su veoma važni prilikom nabavke Pultruzijskih rezuina. Koriste se najmodernije Pultruzijske rezuine i ponudjena je kvalitetna potpora kupcima za tehničku osnovu. Ponuđuje neprekidnu podršku i pomoć prije, tijekom i posle prodaje kupcima.

Квалитет:

Rezine za pultruziju su drugi važni kompozitni materijali koji zaslužuju pažnju, a kvalitet je jedan od ključnih aspekata na koje treba da se obraća pažnja prilikom izbora kompozita. Rezine za pultruziju moraju biti visokog kvaliteta, a formulacije i testovi trebaju da budu u skladu sa industrijskim standardima. Pripremaju se takođe na kontroliran način kako bi se postigli željeni karakteristike materijala i njegova performansa.

Primena:

Vrsta rezina za pultruziju koja se koristi treba da bude usmerena prema namenjenoj primeni. Različite vrste rezina su korisnije u određenim situacijama nego u drugim primenama. To omogućava da se dobijaju najbolji rezultati kao što su efikasno optimizirane kuhinje režima. Time pronalazimo da su najbolje rezine za pultruziju Rešina za ručno lepljenje pojačale osobine proizvoda, a nekoliko industrij može dati plodne rezultate.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

ID

ID

LV

LV

SR

SR

VI

VI

GL

GL

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

AZ

AZ

BN

BN

LA

LA

MN

MN

NE

NE

KK

KK

UZ

UZ