În această articol, vom discuta despre un proces particular numit producție RTM. Și acesta ne permite să producem multe lucruri. Ai auzut vreodată de el? Acest proces denumit (RTM sau resin transfer molding). Este un proces pentru fabricarea obiectelor din plastic și alte tipuri de materiale. Fangxin este una dintre aceste companii care adoptă acest proces excitant. Ei folosesc producția RTM pentru a produce diferite tipuri de produse pe care le putem întâlni în viața de zi cu zi.

Ce este producția RTM?

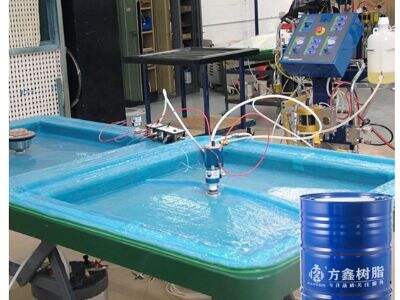

Deci, ce este atunci producția RTM? O matrice este un tip de recipient care modelează produsele pe care le fabricăm. Matricea constă în general din două părți care se potrivesc una cu cealaltă. În timpul injectării resinelor, acestea vor umple spațiul gol dintre cele două părți. Odată inserat cu această Fangxin Rtm resin , apoi forma este încălzită. La răcire și solidificare, se deschide, ceea ce ne dă piesa. Este realizat printr-un proces foarte adaptabil, creând astfel forme și disene diferite.

De ce să folosiți producția RTM?

Unele dintre beneficiile excelente asociate cu acest proces sunt că produsele pe care le generează sunt de înaltă calitate. Ne permite să fabricăm componente care sunt foarte detaliate și estetice. De exemplu, dacă am vrea să facem un jucărie sau orice fel de mobilier, de exemplu decorații, producția RTM ne permite să o producem exact așa cum vrem să o vedem.

Al doilea avantaj major al producției RTM este viteza sa. Acest lucru îi permite să producă multe produse într-un timp scurt. Cu toate acestea, pentru afaceri care au nevoie să producă multe lucruri repede, aceasta este ceea ce ei necesită. Imaginați-vă o companie de jucării care trebuie să producă mii de jucării înainte de sezonul sărbătorilor. Cu toate acestea, producția RTM face posibil această eficiență.

Fluxul de proces pentru producția RTM

Acum, să ne concentrăm pe etapele importante implicate în procesul de fabricație RTM.

Pasul 1: Fabricarea formei — această etapă este dedicată creării formei. Acest lucru se realizează prin unirea a două părți pentru a crea un vas. Fangxin Resină VARTM este aplicată pe o formă îmbinsă cu substanțe speciale cunoscute ca agenți de eliberare, astfel încât resina să nu adere.

Pasul 1: Injectarea resinii – Următorul pas este injectarea resinii în forma ta. Ceea ce o face să funcționeze este forța; în acest fel, resina este forțată să acopere toate detaliile fine ale formei, asigurându-se că acestea sunt complet umplute cu resina. Dacă produsul final nu completează toate detaliile cu resina, arată prost.

Solidificarea resinii: Odată ce resina este în formă, aceasta este închisă bine și plasată într-un cuptor. Cuptorul încălzește forma și ajută la solidificarea resinii. Acesta este un proces cunoscut drept solidificare. Odată solidificată, forma iese din cuptor și este deschisă.

Eliminarea Produsului — Ultimul pas implică scoaterea produsului final din formă. Acest lucru se realizează prin separarea cu grijă a celor două părți ale formețului. După separarea părților, produsul este imediat disponibil pentru utilizare sau vânzare.

Producția RTM vs Alte Metode

Aceasta este puțin mai ridicată producția RTM comparativ cu unele alte forme de fabricație a produselor. Există multe avantaje ale producției RTM față de alte metode de modelare. Modelarea prin injectare — Modelarea prin injectare este o altă tehnică cunoscută pentru producerea de produse plastice. Totuși, modelarea prin injectare are neajunsuri. Este limitată în dimensiunea maximă de construcție, alături de a nu putea produce părți foarte detaliate.

A doua este modelarea prin compresie. Tehnica utilizează materiale presate împreună pentru un produs. Cu toate acestea, compresia este foarte lentă și produce cantități de loturi foarte mici. În general, prin urmare, este mult mai puțin economică pentru majoritatea firmești decât producția RTM.

Legat: Cum promovează producția RTM produse mai bune și economii de costuri?

Există multe caracteristici în care produsele RTM pot îmbunătăți produsele. Aceasta le conferă rezistența și greutatea mică care este atât de necesară în obiectele cotidiene. De asemenea, are capacitatea de a produce părți mai mari și mai complexe. Adică, producția RTM permite părți care ar fi foarte dificile sau chiar imposibile cu alte metode.

Producția RTM nu îmbunătățește doar produsele, ci economisește și bani. Economisește timp, deoarece este o procedură rapidă care poate produce mai multe produse în cadrul procesului său. Crește numărul net de produse produse și reducă costurile muncii, deoarece sunt necesari mai puțini muncitori pentru a produce o cantitate fixă de produs. Producția RTM poate, de asemenea, să minimizeze deșeurile. Mai mult, resină rămasă după finalizarea unui produs poate fi de obicei reutilizată în următoarea serie de producție, făcând-o mai durabilă.

În sfârșit, producția RTM este un proces care permite fabricarea de produse de calitate la un ritm rapid. Fangxin este o companie care utilizează RTM pentru a produce multe dintre produsele tipice ale comerțului cu detalii. Pentru mai multe informații despre Fangxin Rezină de infuziune RTM prin vacum producție, sau pentru a vedea exemple de produse fabricate în acest proces uimitor, accesați site-ul nostru. Sperăm că vi s-a părut util și interesant.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

ID

ID

LV

LV

SR

SR

VI

VI

GL

GL

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

AZ

AZ

BN

BN

LA

LA

MN

MN

NE

NE

KK

KK

UZ

UZ